News information

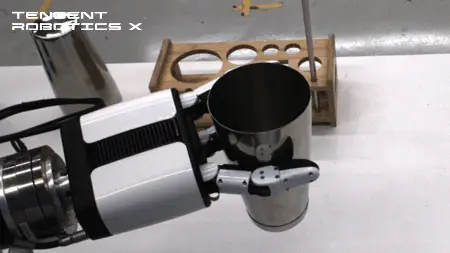

From Sci-Fi to Reality: The Secret Behind Robot Dexterous Hands

What Makes Dexterous Hands So Special?

The Power of Dexterous Hands

Dexterous hands are essential for robots to interact with their surroundings, significantly expanding their applications across various industries:

• Industrial Manufacturing

• Electronics Industry: Precisely handling tiny electronic components like chips, resistors, and capacitors, assembling them onto circuit boards.

• Automobile Manufacturing: Assisting in assembling engines, interiors, and other complex components to enhance efficiency and precision.

• Medical Sector

• Surgical Robots: Performing minimally invasive procedures with extreme precision under a doctor’s remote control, reducing trauma and accelerating patient recovery.

• Rehabilitation Robots: Assisting patients in hand function training to improve rehabilitation outcomes.

• Everyday Services

• Household Robots: Cleaning, dishwashing, and organizing objects to make life more convenient.

• Logistics Robots: Efficiently grasping and transporting goods to improve delivery efficiency.

Human Hands vs. Robotic Hands

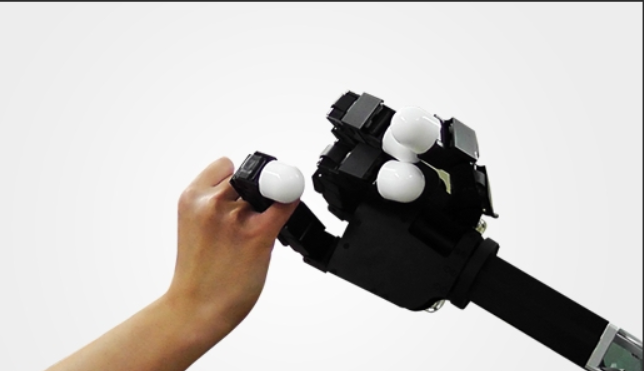

Human hands possess 27 degrees of freedom, allowing for highly refined and coordinated movements like writing, drawing, and playing musical instruments. Despite rapid advancements, robotic hands still face several challenges:

• Limited Degrees of Freedom: The most advanced robotic hands today typically have around 20 degrees of freedom, still falling short of human flexibility.

• Lack of Sensory Perception: While human hands can detect pressure, temperature, and texture through nerve endings, robotic hands still require improvements in tactile sensors for more nuanced touch feedback.

• Smoothness of Motion: Human hand joints perform intricate rotations and bends seamlessly, whereas robotic fingers require sophisticated control systems to achieve similar coordination.

Ball Screw: The Unsung Hero of Dexterous Hands

The primary function of a screw is to convert rotational motion into linear motion, enabling precise control of a robotic hand’s finger movements. Within dexterous hands, lead screws drive finger joints to extend and flex, allowing robots to grasp, pinch, and manipulate objects with precision.

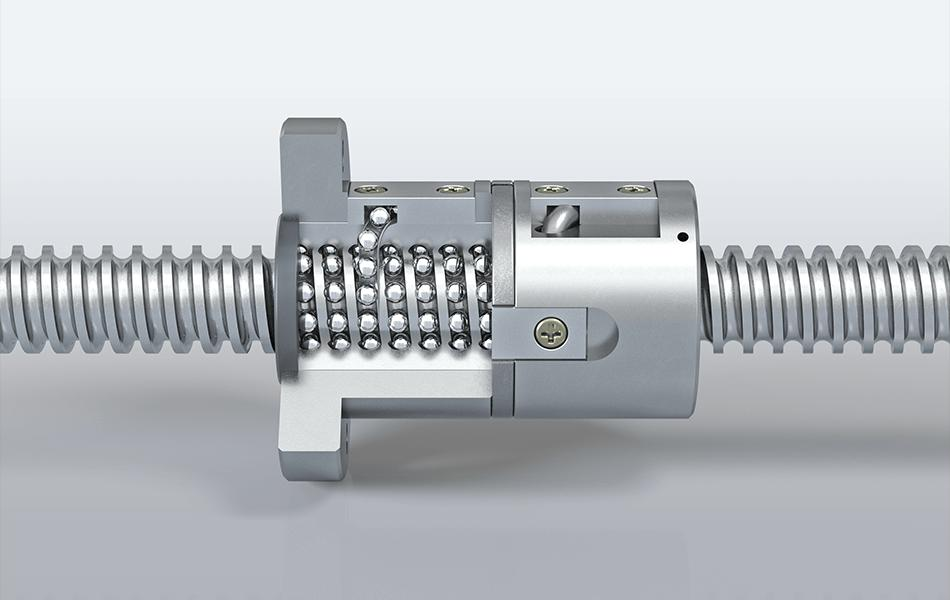

How Do Ball Screws Work?

A ball screw consists of a screw shaft and a nut; as the nut moves along the shaft, it produces an exact linear displacement. For example, when a robotic hand grasps an object, the linear motion screw system precisely drives the finger joints to ensure a stable grip.

Among these, screws are the most commonly used in robotic dexterous hands due to their high precision and efficiency. Meanwhile, planetary roller screws are more suited for applications requiring heavy loads, such as robotic legs.

The High Standards of Ball Screws in Dexterous Hands

Precision: Control at the Micron Level

High precision ball screws and nut used in dexterous hands typically require a C5-level accuracy, meaning an error of no more than ±15μm within a 300mm range (about one-third the diameter of a human hair). Such precision ensures that robotic hands can handle tiny objects without deviation.

Load Capacity: Grasping Objects of Various Weights

Dexterous hands must be able to hold objects ranging from lightweight electronic components to tools weighing several kilograms. This requires screws with sufficient load-bearing capacity to ensure a firm grip without slippage.

Size and Weight: Compact Yet Powerful

ball screw for robotic hands must be small and lightweight to enable flexible movements while maintaining high strength and durability for long-term use.

Perfect for Dexterous Hands: The 4mm Diameter, 1mm Lead, C3 (P3) Ball Screw

This 4mm diameter, 1mm lead, C3 (P3) precision ball screw offers an excellent combination of high precision and compact design, making it an ideal choice for dexterous hands. With its low friction and high load capacity, it ensures smooth, efficient motion control, enabling delicate and intricate movements. The C3 (P3) grade precision guarantees minimal backlash, making it perfect for tasks that require micron-level accuracy and reliability. Its compact size provides the agility needed for versatile operations while still maintaining powerful performance for various gripping and manipulation tasks.

The Future of Robotic Dexterous Hands

As artificial intelligence, materials science, and precision engineering continue to advance, robotic dexterous hands will undergo significant breakthroughs:

• Higher Degrees of Freedom: Overcoming the 27-degree limitation to make robotic hands as flexible as human hands.

• Enhanced Sensory Capabilities: Integrating artificial skin and advanced tactile sensors to improve touch perception.

• Smarter Motion Control: Combining AI and deep learning to enable robotic hands to adapt and optimize their grasping strategies autonomously.

In the future, dexterous hands will revolutionize industries such as manufacturing, healthcare, and service sectors, unlocking new possibilities for human-robot collaboration.

Want to learn more about how ball screws enhance the precision and agility of robotic dexterous hands? Contact us today to explore cutting-edge transmission solutions and take your automation projects to the next level!

NEWS & EVENTS