News information

Ball Screws vs. Hydraulic Systems: The Future of Industrial Automation?

Ball Screws vs. Hydraulic Systems: The Future of Industrial Automation?

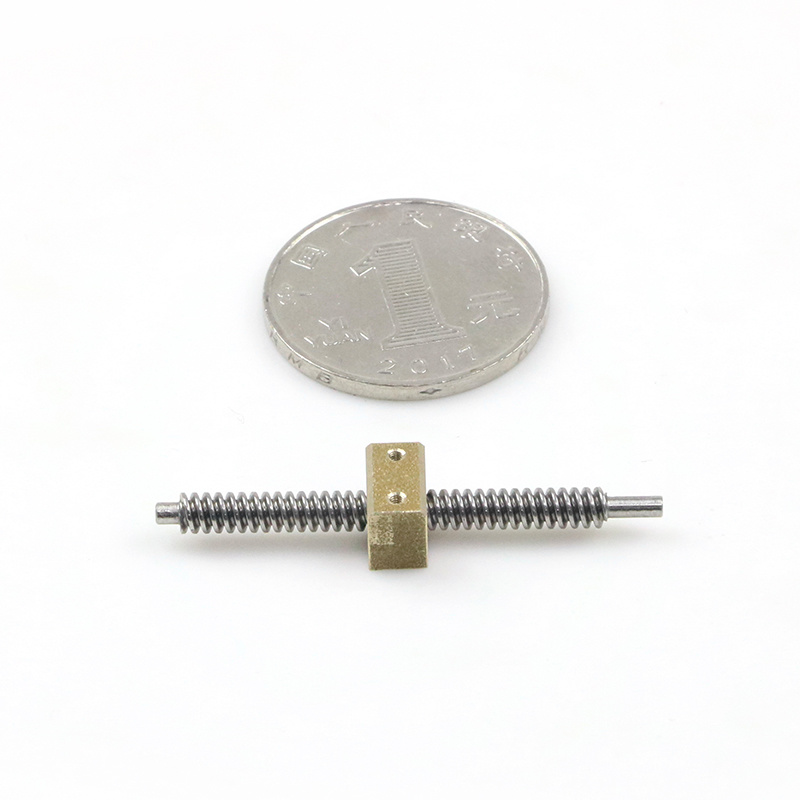

In industrial automation and precision manufacturing, choosing the right transmission system directly impacts efficiency and product quality. Hydraulic systems have long been the standard, but in recent years, ball screws have gained popularity due to their high precision and efficiency. Some even believe that ball screws are replacing hydraulic systems. But is that really the case? Let’s take a closer look.

Why Are More Companies Choosing Ball Screws?

1. Higher Precision, Lower Error Rates

For applications requiring precise positioning—such as CNC machines, semiconductor manufacturing, and medical equipment—ball screws offer a significant advantage. By using rolling friction instead of sliding friction, they minimize energy loss and ensure more accurate motion. In contrast, hydraulic systems are more susceptible to temperature changes, fluid leakage, and long-term accuracy issues.

2. Greater Energy Efficiency, Lower Operating Costs

Ball screws boast a transmission efficiency of over 90%, while hydraulic systems tend to lose energy due to fluid resistance and other inefficiencies. Higher efficiency means lower power consumption, making ball screws a cost-effective choice for long-term operations.

3. Easier Maintenance, Less Downtime

Hydraulic systems require frequent oil changes and regular cleaning to prevent buildup that could affect performance. Ball screws, on the other hand, require only periodic lubrication and wear inspections, reducing maintenance costs and minimizing equipment downtime.

Hydraulic Systems Still Have Their Place, but Ball Screws Are the Future

While hydraulic systems remain the go-to solution for heavy-load applications like construction machinery, advancements in ball screw technology are closing the gap. Today, ball screws can handle increasingly higher loads and meet the demands of most industrial automation applications.

For businesses seeking higher precision, better efficiency, and lower maintenance costs, ball screws are the smarter choice.

Looking to upgrade your equipment?

A high-precision ball screw could be exactly what your system needs. If you’re considering making the switch, check out our selection and find the right fit for your application. Our team is here to help—reach out, and we’ll get back to you within two hours!

NEWS & EVENTS